A high-speed, high-quality production system specialized in the processing of guide wires for medical catheters

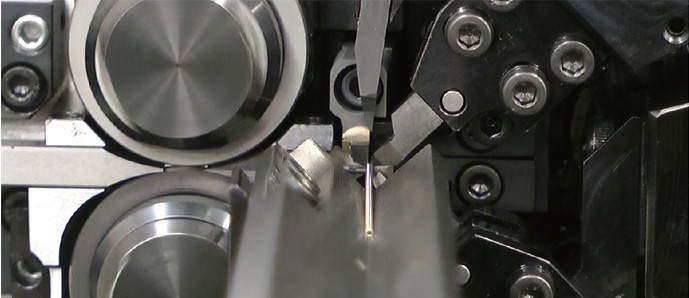

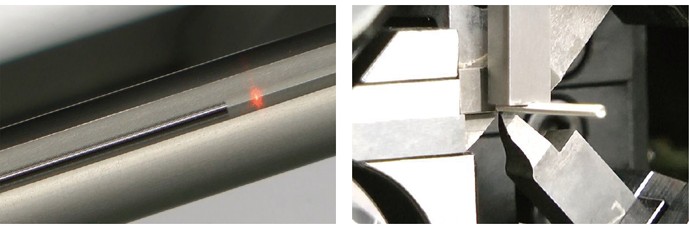

2-Point Coiling Spring Machine for Guide Wires Processing

The newly developed 2-point coiling unit disperses friction during coiling and contributes to stabilization of the initial coil tension. Furthermore, compared to the 1-point method, the trace of the coil inner diameter is greatly reduced without an arbor.