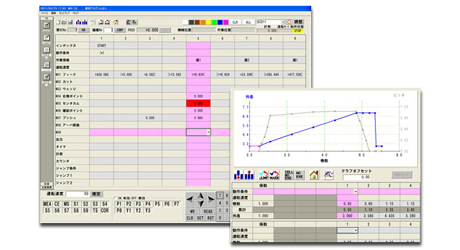

| Standard | Wire Dia. 0.08~0.3mm | Arbor Axis(Option) | Resolution 0.001mm |

|---|---|---|---|

| Outside Dia. 10mm | Solenoid valves | 4pcs(Max 8pcs available) | |

| D/d 4 or more | Air requirements | Max 0.5 MPa | |

| Ultra Fine Wire A/T | Wire Dia. 0.03 ~ 0.08mm | Power source | AC 200V 3-Phase, 15A |

| Feed Axis | Resolution 0.001mm | Net weight | 400㎏ |

| Cut Axis | Resolution 0.001° | Control device | Max. 9-axis to be controlled by computer - OS Windows XP |

| Pitch Axis | Resolution 0.001mm | ||

| Point Axis | Resolution 0.001mm | Display | 17'' TFT color LC Display |

| Torsion A/T Axis | Resolution 0.001° | External memory | USB thumb drive |

| Initial tension Axis | Resolution 0.001mm | Service Temp. | 0~40 deg. C(32-104 deg .F) |

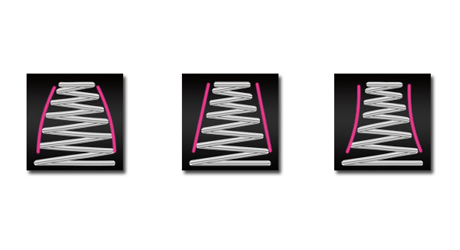

The SH-3A, a multi-functional coiling machine with 1-point coiling, torsion attachment, and an initial tension servo, has further evolved.

This coiling machine can now process an even greater range of torsion springs.