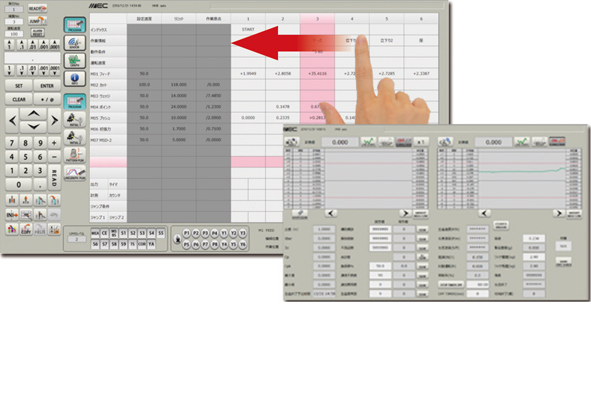

LM-16A Wire Forming Machine

15-axis CNC torsion Spring Machine with Rotating Wire

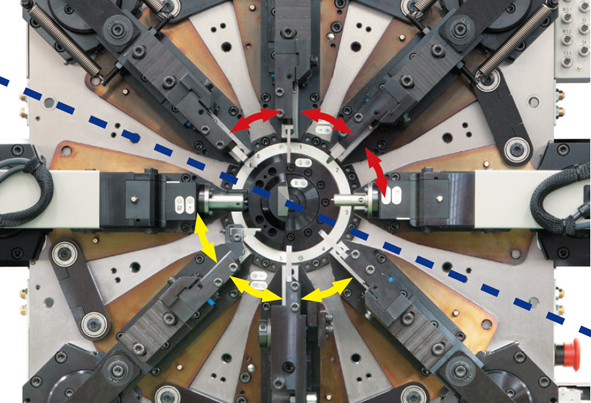

With its wire rotation mechanism and eight processing slides as standard options, the LM-16A provides intuitive operation. Two swinging axes control the left and right movement of the facing slides independently.